In India’s manufacturing, warehousing, and retail industries, caster wheels / castor wheels and trolley wheels are indispensable for moving loads efficiently. However, like all mechanical components, they can develop problems over time. If not diagnosed early, these issues can lead to operational downtime, safety risks, and costly replacements. Knowing how to troubleshoot common caster wheel problems can help Indian businesses extend equipment life and improve workplace safety.

Here’s a detailed guide to diagnosing and resolving common issues with caster wheels:

-

Uneven or Excessive Wear

One of the most frequent problems is uneven wheel wear. This can be caused by poor floor conditions, overloading, or incorrect wheel material.

Diagnosis: – Check for flat spots or peelings on softer wheels like polyurethane, rubber wheels and pvc wheels. – Look for chips and cracks on PP or Nylon wheels. – Inspect whether only one wheel in a set is wearing out faster.

Solution: – Match wheel material to floor type (e.g., polyurethane for tiles/epoxy, nylon for rough concrete). – Ensure the load capacity per wheel is not exceeded.

-

Caster Flutter or Wobble

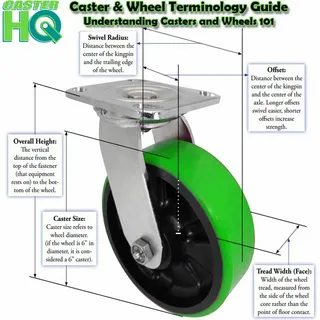

Caster flutter (rapid side-to-side oscillation) often occurs in swivel castor wheels at higher speeds.

Diagnosis: – Check if the swivel bearing is loose or damaged. – Inspect wheel alignment and offset dimensions.

Solution: – Tighten swivel raceways or replace worn bearings. – Use precision ball-bearing casters for smoother rotation.

-

Difficulty in Swiveling or Rolling

When trolley wheels become hard to move, it increases operator fatigue and slows down workflow.

Diagnosis: – Check if the bearings are jammed due to dust or debris. – Inspect for rust or lack of lubrication. – Ensure that mounting plates are not bent.

Solution: – Clean and lubricate wheel and swivel bearings. – Replace damaged or corroded components.

-

Noise Issues

Excessive noise during trolley movement can be disruptive, especially in hospitals, offices, and retail stores.

Diagnosis: – Inspect for worn-out bearings or hardened wheel treads. – Check for debris stuck inside the wheel tread. – Identify if the floor type is amplifying vibration.

Solution: – Use elastic rubber or polyurethane wheels for quieter operation. – Replace noisy ball bearings with sealed precision bearings.

-

Brake Malfunction

Brakes are crucial for safety, especially in warehouses, hospitals, and sloped environments.

Diagnosis: – Test if the brake engages and releases smoothly. – Check for worn or bent brake levers. – Inspect whether the brake pads grip the wheel properly.

Solution: – Adjust or replace faulty brake mechanisms. – Upgrade to anti-skid caster wheels for slippery floors.

-

Wheel Misalignment or Fork Bending

Heavy loads or impacts against obstacles often cause fork bending.

Diagnosis: – Observe if the trolley pulls to one side. – Check if one wheel is tilted compared to others.

Solution: – Replace bent forks immediately. – Train operators to avoid hitting obstacles at high speed.

-

Floor Damage from Wheels

Improper wheel selection can cause scratches, dents, or cracks in flooring.

Diagnosis: – Look for black streaks, cracks, or chipping on floors under trolley routes. – Identify if the wrong wheel material (e.g., cast iron on Epoxy) is in use.

Solution: – Switch to floor-friendly caster wheels such as polyurethane or elastic rubber.

Conclusion

For Indian businesses where trolley wheels and caster wheels are in constant use, diagnosing problems early is essential. A structured troubleshooting process helps reduce downtime, prevent accidents, and cut replacement costs. Whether it’s a warehouse in Bengaluru, a hospital in Mumbai, or a retail mall in Delhi, maintaining healthy caster wheels ensures efficiency and safety.

Pro Tip for Indian Users: Always keep a small stock of spare wheels and bearings for quick replacement. This minimizes downtime and ensures uninterrupted operations.