In the ever-evolving world of custom apparel, a new printing technique is making waves—Direct to Film (DTF) printing. This method offers a groundbreaking approach to creating vibrant, durable, and flexible designs on a wide range of fabrics. Whether you’re a fashion entrepreneur or a hobbyist, understanding how this technique works and why it’s gaining traction is essential.

This article explores everything you need to know in The Ultimate Guide to DTF Printing: How It Works and Why It’s Revolutionizing Apparel Design.

What is DTF Printing?

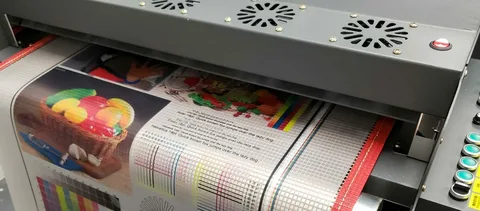

DTF printing, short for Direct to Film printing, is a digital transfer process that involves printing designs onto a special film and then transferring them to fabric using a heat press. Unlike traditional screen printing or even Direct to Garment (DTG) printing, DTF can be applied to almost any type of fabric—including cotton, polyester, blends, and more—without pre-treatment.

How Does It Work?

The DTF printing process involves several key steps:

- Print on Film: The design is first printed in reverse on a PET (polyethylene terephthalate) film using a specialized DTF printer with textile-grade pigment inks.

- Apply Adhesive Powder: A hot-melt adhesive powder is applied to the printed film while the ink is still wet.

- Cure the Design: The film is then heated to melt the adhesive, ensuring it bonds properly with the ink.

- Transfer to Fabric: Using a heat press, the film is applied to the garment. After a short press, the film is peeled away, leaving the design on the fabric.

This streamlined process makes DTF ideal for short runs, custom orders, or complex designs that would be difficult or expensive with traditional methods.

Why DTF Printing is Revolutionizing Apparel Design

The Ultimate Guide to DTF Printing: How It Works and Why It’s Revolutionizing Apparel Design wouldn’t be complete without diving into the benefits that are causing designers and businesses to adopt this method in droves.

1. Versatility Across Fabrics

DTF printing works on a wide variety of fabrics, including both natural and synthetic fibers. This flexibility is a major advantage over DTG printing, which typically requires high-cotton content for the best results.

2. High-Quality Output

Designs printed via DTF are vibrant, highly detailed, and resistant to cracking or fading. This makes it a top choice for brands that prioritize both aesthetics and durability.

3. Cost-Effective for Small Batches

Unlike screen printing, which requires setup costs for each color, DTF printing is a digital process. This makes it ideal for small batches or one-off designs without the extra costs or waste.

4. Easy Customization

Need to print a dozen shirts with different names or numbers? DTF makes it fast and simple. You can swap out design elements on the fly without interrupting the workflow.

DTF vs. DTG and Screen Printing

When comparing DTF to DTG (Direct to Garment) and screen printing, each method has its pros and cons. However, DTF stands out for its ability to print on nearly any material and its low startup costs for new businesses.

| Feature | DTF Printing | DTG Printing | Screen Printing |

| Fabric Compatibility | All types | Mostly cotton | All types |

| Setup Cost | Low | Medium | High |

| Color Range | Unlimited (CMYK) | Unlimited (CMYK) | Limited by screen count |

| Ideal for Small Runs | Yes | Yes | No |

Final Thoughts

As this method gains popularity, more printers, designers, and apparel companies are turning to Direct to Film as their go-to solution for vibrant and long-lasting prints. Whether you’re new to custom printing or looking to upgrade your production process, The Ultimate Guide to DTF Printing: How It Works and Why It’s Revolutionizing Apparel Design should serve as your roadmap to getting started.

By embracing this innovative method, you’re not just keeping up with the times—you’re staying ahead of the curve in modern apparel design.